.png)

Machine Tools Industry

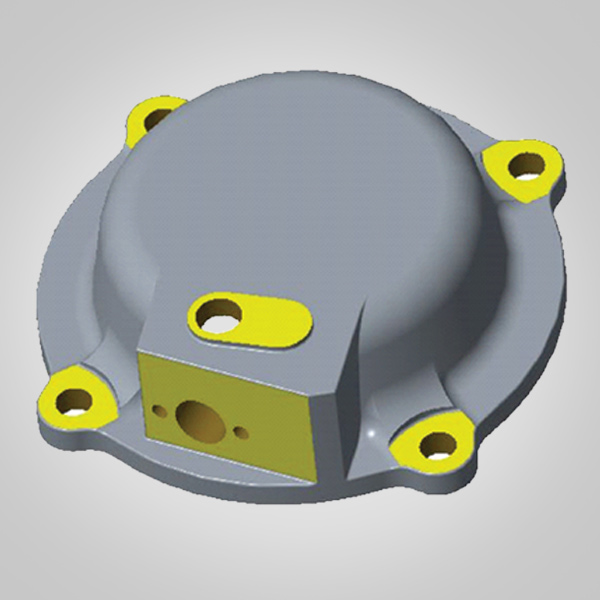

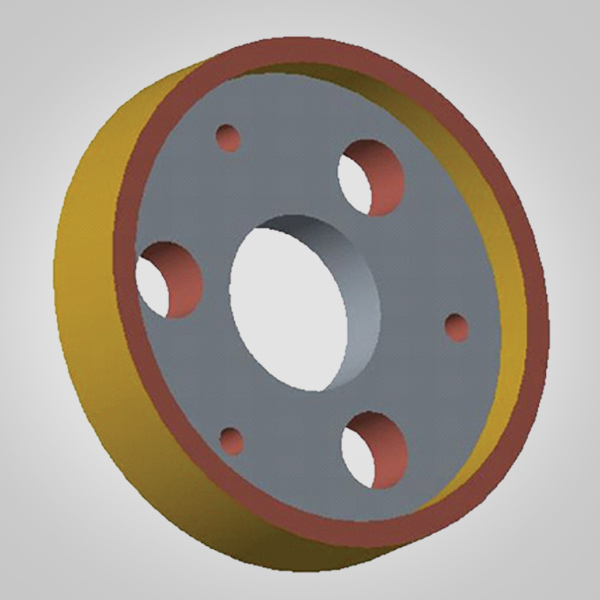

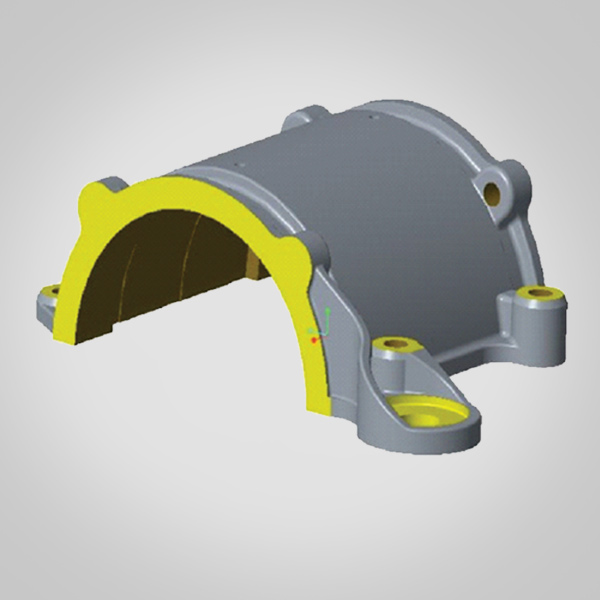

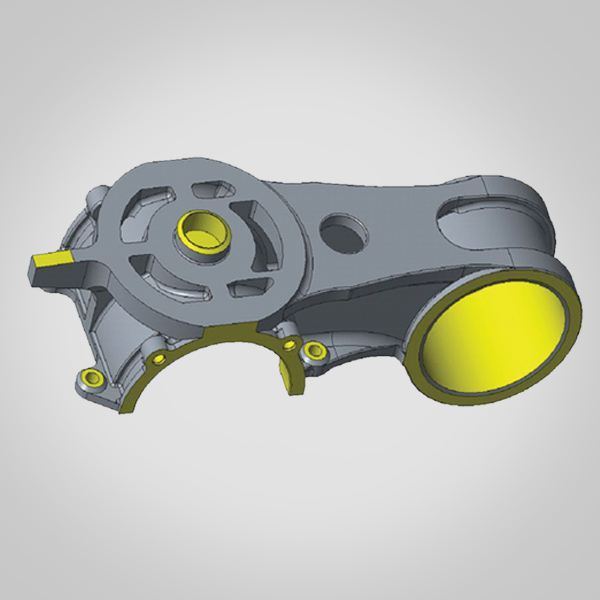

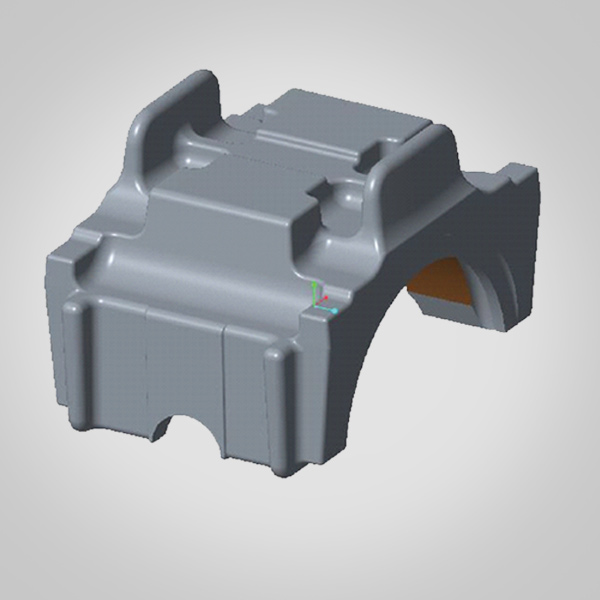

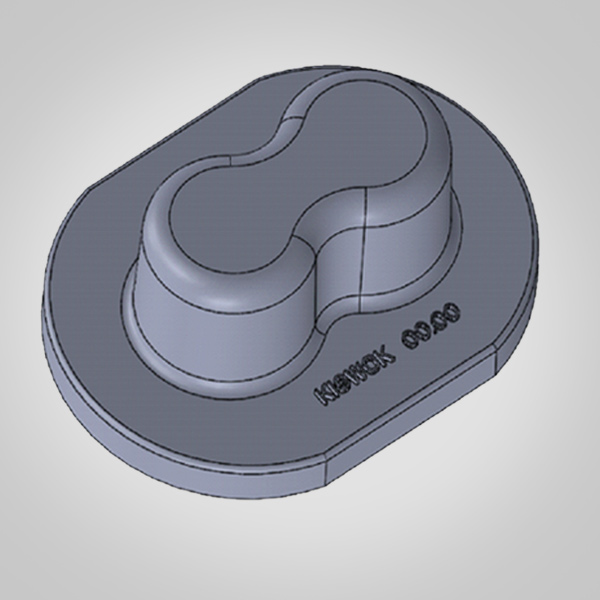

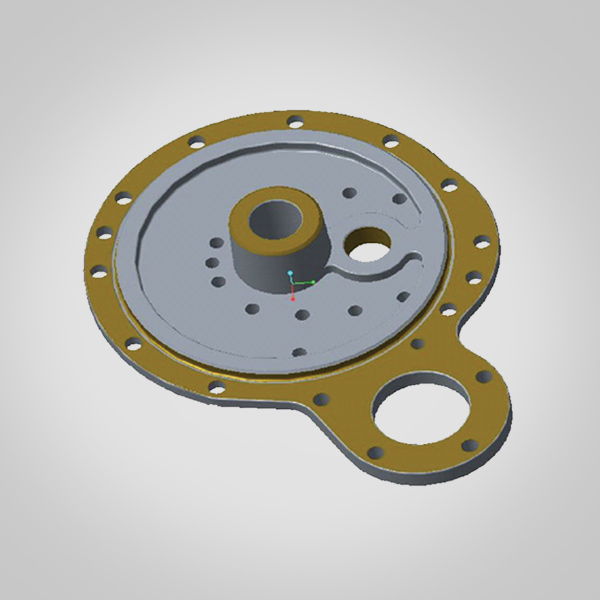

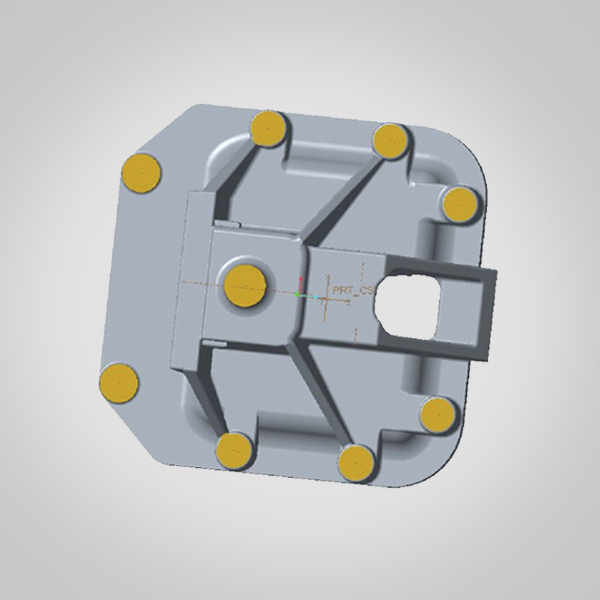

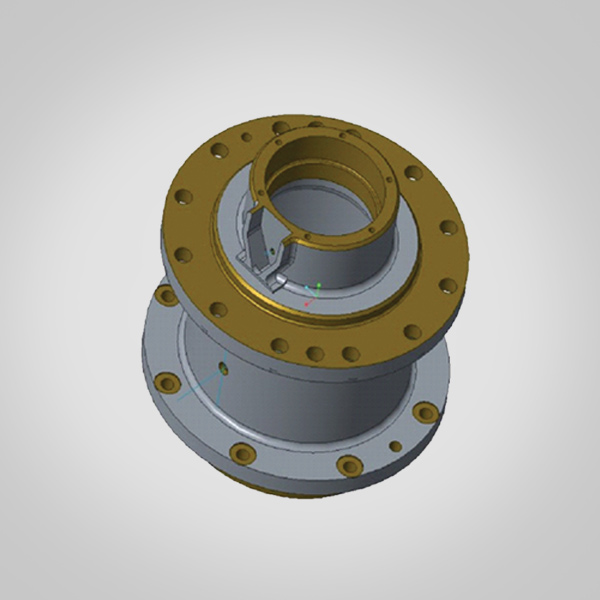

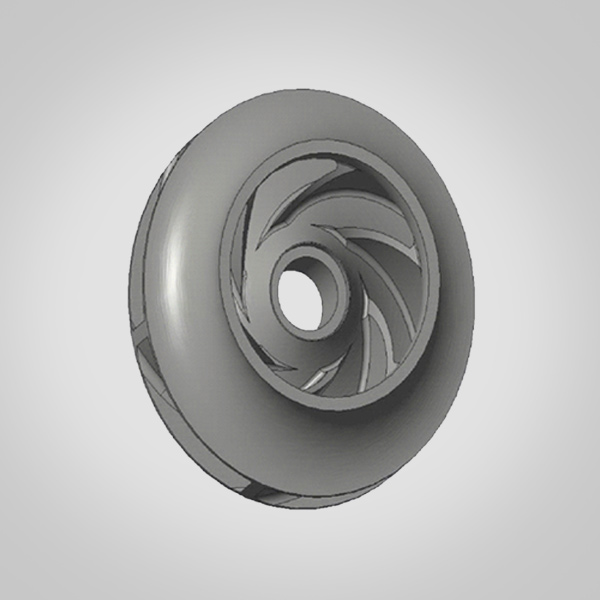

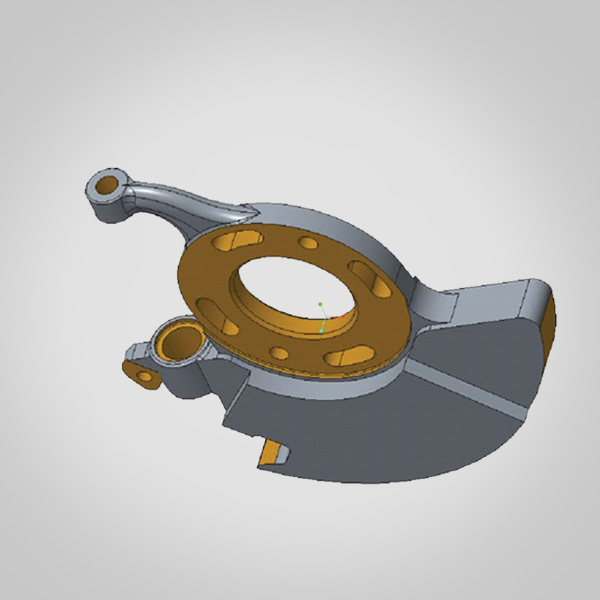

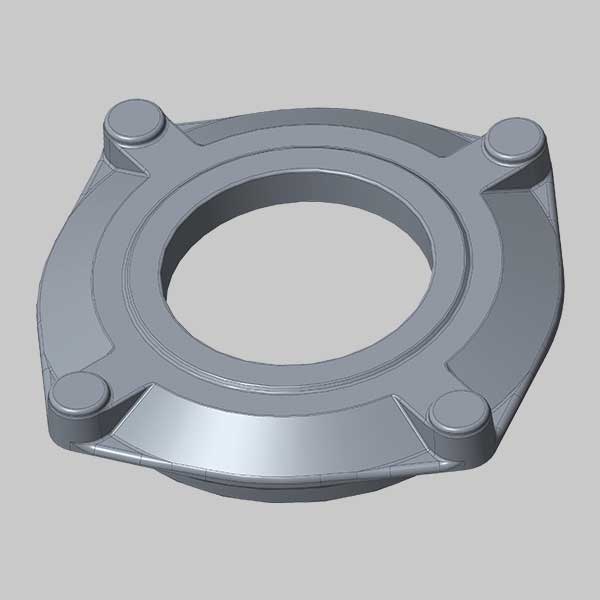

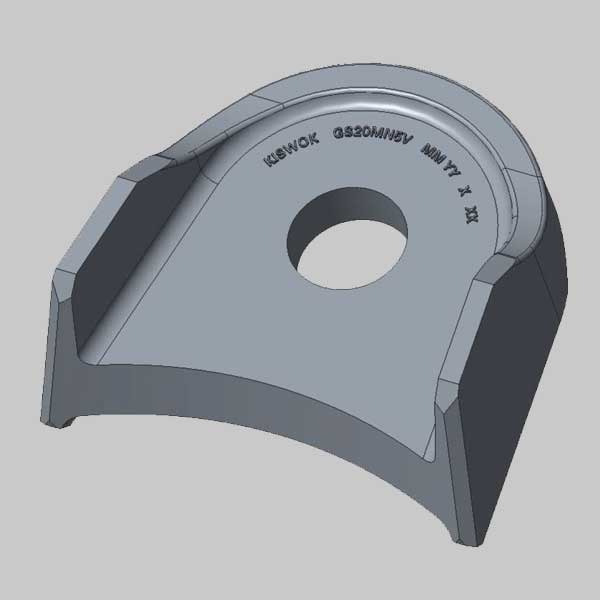

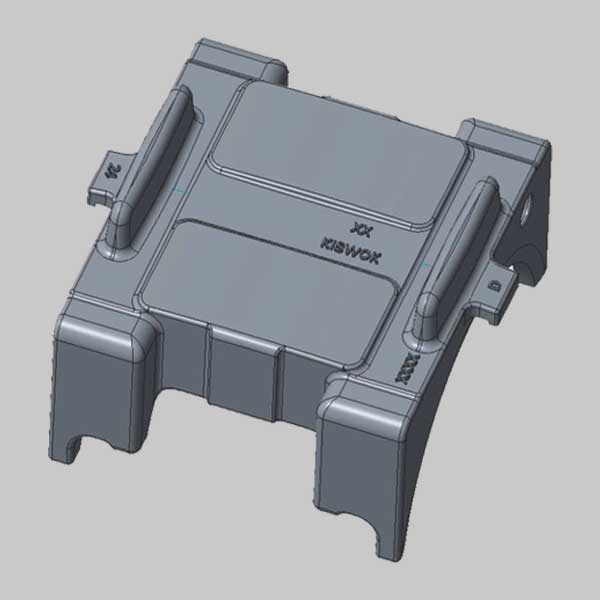

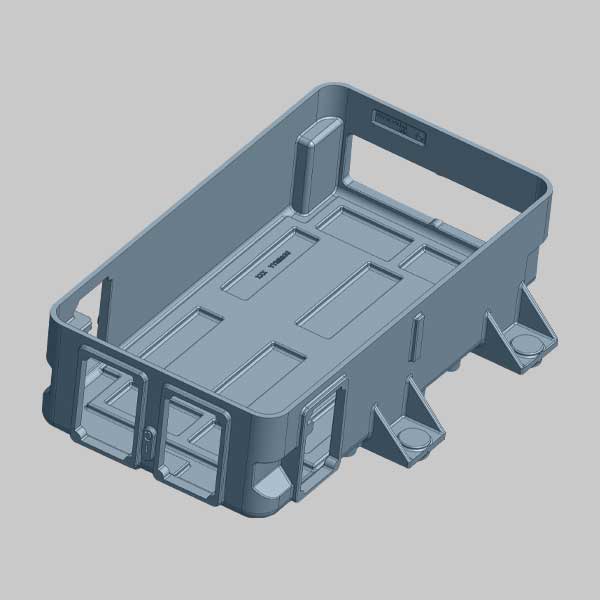

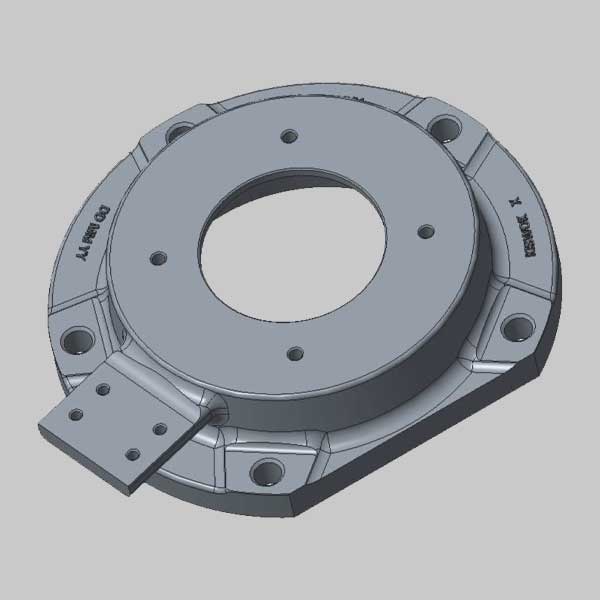

Using advanced molding and casting techniques, we shape premium materials into

reliable machine tool components. From bases and frames to intricate machine parts,

our castings enhance operational efficiency, reduce wear, and support the long-term

performance of modern manufacturing equipment.

At Shree Durga Foundry, we provide high-quality castings for the machine tools

industry, ensuring precision, durability, and superior performance. Our cast

components are designed to meet the rigorous demands of industrial machinery,

offering exceptional strength and stability for critical applications.